info@Lipp-ats.com

616.201.6761

29770 Hudson Drive,

Novi, Michigan 48377

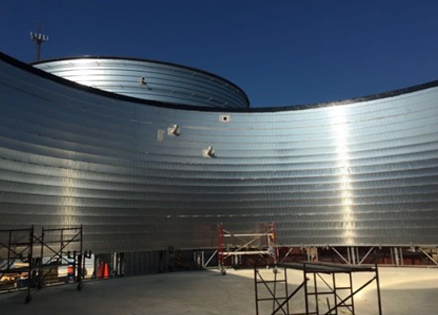

As early as 1970, Xaver Lipp had the idea for unique double-fold system, which signified a quantum leap in the field of tank technology and has stood the test in the construction of containers and tanks in innumerable plants to the present day.The system involves steel bands being interlinked by folds giving the inside of the container an edgeless and smooth surface. Additionally, the double-fold system guarantees maximum tightness and stability.

The LIPP System has already been successfully used in more than 80 countries!

The Special “Double-Fold” System | VERINOX Interior Lining System

A stainless-steel band and a galvanized steel band are joined with a separation layer. As a result, the proportion of expensive stainless steel is reduced considerably, as are the total costs. The material quality of the Interior stainless-steel band layer is variable, depending on Project requirements – 316 L /316 Ti / 904 / 2205 Duplex Alloy are all available depending on each project.

With Verinox – this duplex material which has been developed by the Lipp organization, is made up of a sheet of stainless steel which is joined to a sheet of galvanized steel by means of a separation layer. An adhesive sheet is rolled and compressed (sandwiched) between the carbon and stainless alloy. This allows the Barrier to be created so as to provide protection of dis-similar metals to occur.

Three components form the basis for this material that is ideal for tank construction. Not only does it have outstanding physical properties but it also uses a reduced quantity of expensive stainless steel, resulting in lower costs.

There are no open joints due to the folded design. Various grades of stainless steel are suitable for use inside tanks. A simple steel or galvanized sheet is sufficient for the outside of the tanks as it will be corrosive resistant and able to withstand normal weather conditions.

The unique Lipp System construction method ensures the highest levels of quality when storing, liquid and gaseous substances. Our double-fold tank assembly systems are built using American raw materials. For more than 50 years, this family-owned company has offered high-quality steel tanks and system solutions across the world.

Lipp America Tank Systems, LLC

29770 Hudson Drive

Novi, Michigan 48377

a.lettinga@lipp-ats.com

616.201.6761 | 616.813.3600